CT Plus 3D Printing Creates Custom-Designed Middle Ear Temporal Bones

CT combined with 3D printing accurately reproduced damaged parts of the middle ear.

Computed tomography scans and 3D printing can create accurate, custom-designed prosthetic replacements for damaged parts of the middle ear, according to a study presented at

The researchers explored whether custom 3D printing an individualized ossicular prosthesis would be a potential solution for the wide range of anatomic variation encountered in the pathological middle ear, and could decrease the rate of post-operative prosthesis displacement by increasing the likelihood of a proper fit, in addition to decreasing surgical time.

"The ossicles are very small structures, and one reason the surgery has a high failure rate is thought to be due to incorrect sizing of the prostheses," coauthor Jeffrey D. Hirsch, MD, an assistant professor of radiology at the University of Maryland School of Medicine (UMSOM) in Baltimore, said in a release. "If you could custom-design a prosthesis with a more exact fit, then the procedure should have a higher rate of success."

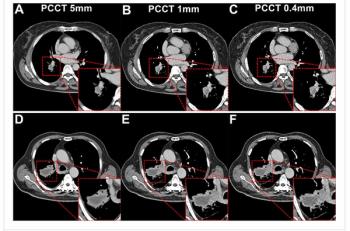

The researchers removed the incus from three formalin-fixed cadaveric human temporal bones with no macro- or microscopic evidence of pathology. Imaging of the cadaveric bone was obtained using a standard temporal bone CT protocol. A custom prosthesis for each cadaveric human temporal bone was designed and then fabricated on a 3D printer. Four surgeons then performed insertion of each prosthesis into each middle ear, blinded to the bone from and for which each was designed. The surgeons were then asked to match each prosthesis to its correct parent bone.

The results showed each prosthesis had unique measurements and each of the four surgeons was able to correctly match the prosthesis model to its intended temporal bone. The chances of this occurring randomly are 1:1296, the researchers reported.

"This study highlights the core strength of 3-D printing - the ability to very accurately reproduce anatomic relationships in space to a sub-millimeter level," Hirsch said. "With these models, it's almost a snap fit."

[[{"type":"media","view_mode":"media_crop","fid":"64678","attributes":{"alt":"","class":"media-image media-image-right","id":"media_crop_5147660555898","media_crop_h":"0","media_crop_image_style":"-1","media_crop_instance":"8285","media_crop_rotate":"0","media_crop_scale_h":"0","media_crop_scale_w":"0","media_crop_w":"0","media_crop_x":"0","media_crop_y":"0","style":"float: right; height: 300px; width: 400px;","title":" 3D printed prosthesis implant. ©RSNA 2017.","typeof":"foaf:Image"}}]]

Newsletter

Stay at the forefront of radiology with the Diagnostic Imaging newsletter, delivering the latest news, clinical insights, and imaging advancements for today’s radiologists.