Secrets to Achieving Quality Improvement

People are the key to getting results.

Whether it’s patient experience or better image quality, radiology is rife with quality improvement projects geared toward augmenting services rendered.

Regulatory requirements have placed a heavy burden on your shoulders to assess your performance and make changes for growth and furthered excellence. It’s a tall order, according to industry experts, and you can’t tackle every problem you identify headfirst. Instead, you must consider many things if you want to reach your goals.

“We’re living in an environment that changes regularly, and our practices are rapidly growing,” says David Larson, MD, associate professor of pediatric radiology at Stanford University Medical Center. “Technology continues to advance in complexity and explode. Managing it requires different strategies than in the past.”

Consequently, he says, radiology must make use of its best tools. Ironically, for industry quality improvement, that doesn’t mean using the latest-and-greatest electronic toys. It actually means employing your most powerful resource-your people. Leaning on colleagues, staff, and even patients can produce the best quality improvement results.

Maximizing Diversity

When creating a quality improvement team, don’t just draft other radiologists. It’s likely you will all approach a problem from the same vantage point, says Rachel Smith, manager of radiology quality assurance and compliance at Cincinnati Children’s Hospital.

Include your nurses and technologists, she says. As providers closest to your patients, nurses assume a patient advocate role, ensuring you consider patients’ voices in any plans you finalize. Technologists also offer perspective on what changes are feasible and which would present unnecessary hardships in image-gathering.

For example, Cincinnati Children’s radiology quality improvement team includes MRI technologists who split time between clinical and quality improvement responsibilities.

“Creating this type of team gets us closer to the frontline staff because they have peers coming to them with questions about improvement or suggestions for things they want to consider working on,” Smith says. “It’s easier to work on something when someone you know who’s doing the same thing you do brings it to you.”

Including your frontline staff is critical, she says, because without them, quality improvement efforts are more likely to fail. Ask what they want to change or what they see that’s not working. Engaging these individuals frequently leads to securing their buy-in for any initiatives you undertake.

Advisory Groups

Even with input from your colleagues, you can still benefit from garnering patient feedback. Recruiting patients to an advisory group can be an effective way of testing whether your quality improvement efforts will work, Smith says.

If schedules permit, you can plan face-to-face meetings, but virtual groups are also a good option, she says. You can easily query them about potential patient education documents or changes to your intake procedures. Their responses can tell you whether your ideas will work.

This strategy succeeded for Cincinnati Children’s, she says. The department was able to improve patient care after the advisory group supported an idea to give families of patients with programmable shunts a reminder card to have the shunt re-programmed post-MRI.

Project Management

With your quality improvement team established, it’s imperative to manage your project effectively, says Larson, who published an

“Project management is one of the most important parts of quality improvement because quality improvement is all about slowing down and testing things deliberately,” he says.

Two tools are most effective in helping you decide which problems to address, he says.

- Fishbone Diagram: This cause-and-effect

diagram helps you outline the main factors contributing to any quality lapses you experience, such as a lack of standardized terminology when dictating lung CTs. Once listed, you can systematically fix each one, hopefully leading to better quality output. - Pareto Diagram: This diagram showcases how frequently a problem actually occurs. With it, you can see whether the issue you’ve identified is substantial enough to warrant a full-blown initiative.

Data

While your people are the engine behind making quality improvement happen, the lynchpin to success is still data and whether you can harness it, analyze it, and make it actionable.

This is where an intricate understanding of your PACS, RIS, and voice recognition tools is helpful, Larson says. Knowing your way around these technologies facilitates identifying and exporting information needed to thoroughly assess your problems and construct solutions.

Once you’ve mined your data and homed in on trouble spots, Smith says, you can accurately determine the best way to measure your future performance and whether you should apply proposed solutions to multiple areas.

“We pinpoint problems and where they’re happening using data we already have,” Smith says. “It helps us understand what might be a big problem and what might be happening just in one place.”

Using data this way conserves your resources and localizes your efforts to specific targets instead of including ones that won’t benefit from your work, she says.

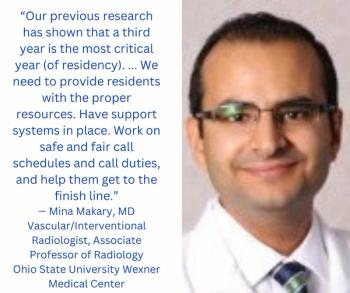

Quality Training Early

Given the ever-louder quality improvement calls, many institutions are giving their residents the skills needed to maximize their service levels.

For example, the University of Minnesota’s radiology department created a quality improvement training program where residents identify problems, recruit technologists and nurses to an improvement team, document the process, and present their outcomes. Faculty serve as mentors who review and critique the work.

In a recent project, residents increased patient information form use with the PACS to decrease the amount of time radiologists search for clinical context around musculoskeletal imaging orders. As a result, the time needed for a radiologist to find relevant information dropped from 46.6 seconds without the form to 15.2 seconds with it. After reading 115 exams, providers saved 1 hour of work time.

Challenges

Time constraints and uncertainty are your biggest barriers to implementing quality improvement initiatives. It can be tempting to simply add a question to your ordering protocol or make a change to your electronic health record, but small steps are unlikely to prompt the quality improvement you seek, Smith says.

Don’t rush for the quick fix. Instead, take your time to map out your plan. Test your strategy after a short time, and don’t get discouraged if you don’t hit a homerun immediately.

“There’s always an opportunity for improvement,” she says. “Don’t feel defeated if you can’t do it right away. Focus on what you can control and what you can do right now.”

Getting started can also be difficult, Larson says. But, don’t shy away from addressing problems because your quality improvement team isn’t perfect. Instead, commit to working methodically toward the best solution.

“A major pitfall can be jumping to action too quickly,” he says. “Recruit individuals in your organization who have at least some background in improvement methods, get started, and learn as you go.”

Just remember, he says, there’s no magic bullet to fix quality woes. It might take several tries to find the right solution. You can increase your chances, though, by letting your colleagues know participating in quality improvement efforts is expected.

“This needs to be part of the job description,” Larson says. “It should be part of on-boarding and training, and it must be embedded into managing everyday operations.”

Newsletter

Stay at the forefront of radiology with the Diagnostic Imaging newsletter, delivering the latest news, clinical insights, and imaging advancements for today’s radiologists.